Processing of bovine hides

Starting with prompt collection of high quality raw material from selected suppliers, to a conscious and responsible handling of hides and skins, including appropriate careful conservation, each step of the way is optimized to maintain product quality.

This is ensured through frequent and regular monthly assessment by the SGS Germany, an external and independent quality manager.

1. Icing

Quality assurance of hides and skins begins directly at the suppliers premises. Prior to collection, the hides are cooled down with ice.

2. Transport

Our fleet of trucks collects hides directly from selected suppliers, promptly after slaughtering.

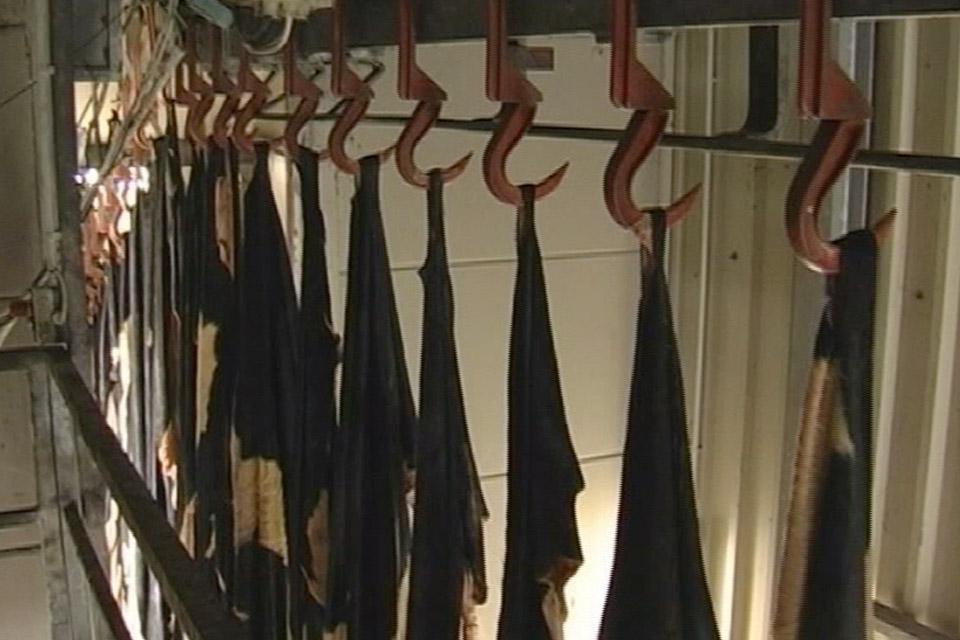

3. Hanging

Upon arrival, each hide is hooked and hung on a pipe transportation system.

4. Trimming of hides

Non-useable parts of the hides and skins are manually removed.

5. Categorising

Each hide is checked in detail and categorized for further processing.

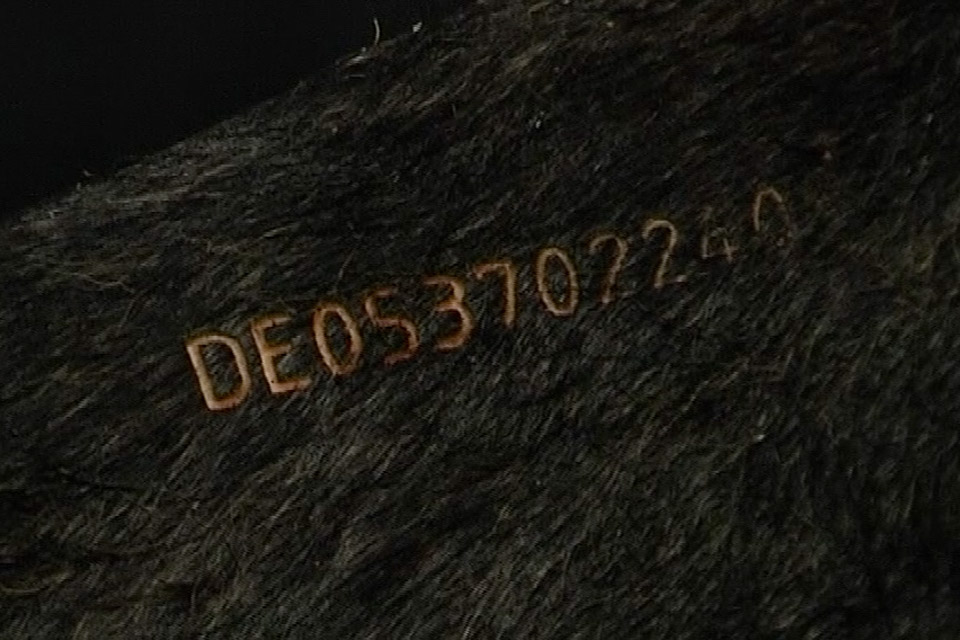

6. Traceability

The ear-tage code of the animal is lasered into the hide to enable traceability.

7. Cooling

Fresh material for Germany and Europe is stored in our refrigerated warehouses until loading.

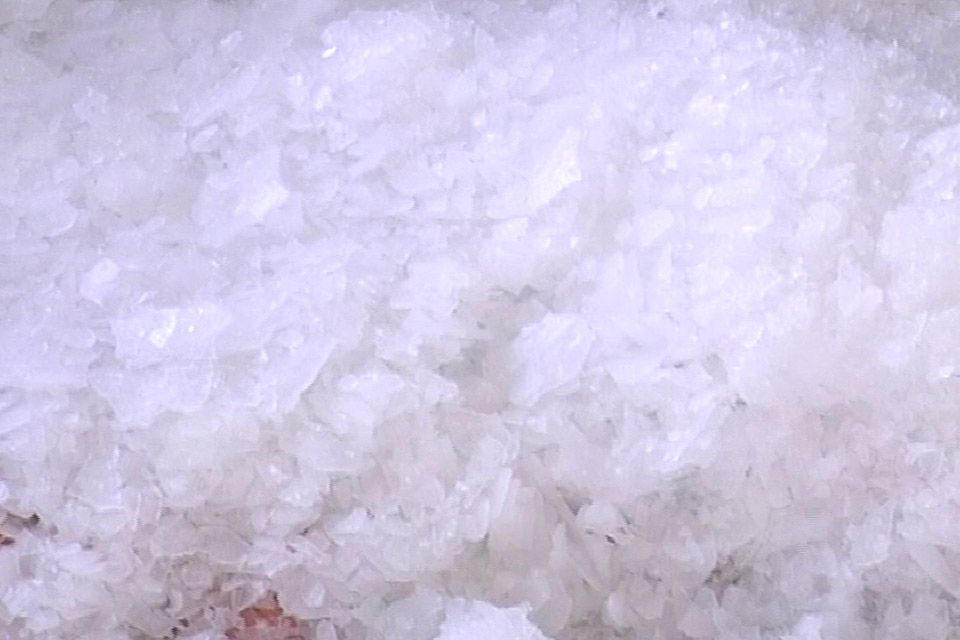

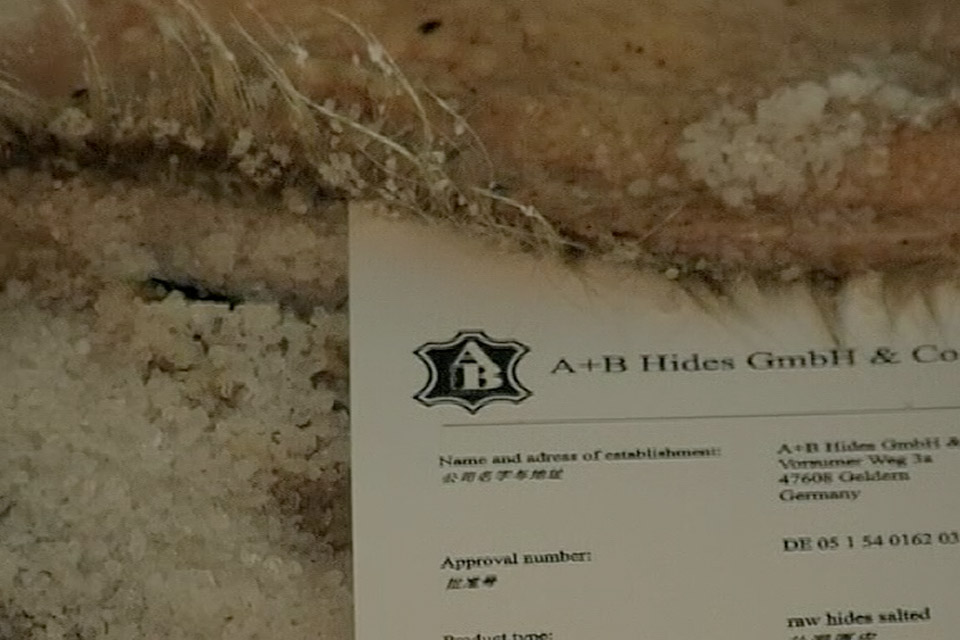

8. Salting

Hides for international clients, for example in Asia, are salted and thus conserved for transport.

9. Selection of salted material

Before shipment, salted hides are checked again and palettized.

10. Storage of salted material

Until shipment, salted hides are stored in their respective selections.

11. Shipment of salted material

Salted material is shipped in overseas containers.

12. Shipment of fresh material

Fresh material is delivered to the client with a core temperature of 2°C.

Quality & Reliability

The image film gives you an insight into the processing of hides, as well as the locations and history of A + B HIDES.

Member of OSI Group

After many years of trusting and successful cooperation A + B Hides GmbH is part of the OSI Group.

Cattle poster

Discover the diversity of German and Austrian cattle breeds. As a download or as a poster order to your home.

Bouvino – leather products

BOUVINO manufactures its products with respect for the origin of the leather – the skins of cattle.